Bond characterization

The wafer bond characterization is based on different methods and tests. Considered a high importance of the wafer are the successful bonded wafers without flaws. Those flaws can be caused by void formation in the interface due to unevenness or impurities. The bond connection is characterized for wafer bond development or quality assessment of fabricated wafers and sensors.

Contents |

Overview

Wafer bonds are commonly characterized by three important encapsulation parameters: bond strength, hermeticity of encapsulation and bonding induced stress.[1]

The bond strength can be evaluated using double cantilever beam or chevron respectively micro-chevron tests. Other pull tests as well as burst, shear or bend tests enable the determination of the bond strength.[2] The packaging hermeticity is characterized using membrane, He-leak, resonator/pressure tests.[1]

Three additional possibilities to evaluate the bond connection are optical, electron and acoustic measurements. At first, optical measurement techniques are optical microscopy, IR transmission microscopy and visual inspection. Secondly, the electron measurement is commonly applied using electron microscopy, e.g. scanning electron microscopy (SEM), high voltage transmittance electron microscopy (HVTEM) and high resolution scanning electron microscopy (HRSEM). And finally, typical acoustic measurement approaches are scanning acoustic microscope (SAM), scanning laser acoustic microscope (SLAM) and C-mode scanning acoustic microscope (C-SAM).

The specimen preparation is sophisticated and the mechanical, electronic properties are important for the bonding technology characterization and comparison.[3]

Infrared (IR) transmission microscopy

Infrared (IR) void imaging is possible if the analyzed materials are IR transparent, i.e. silicon. This method gives a rapid qualitative examination[4] and is very suitable due to its sensitivity to the surface and to the buried interface. It obtains information on chemical nature of surface and interface.

Infrared transmitted light is based on the fact that silicon is translucent at wavelength ≥ 1.2 µm. The equipment consists of a infrared lamp as light source and a infrared video system (compare to figure "Schematic infrared transmission microscopy setup").

The IR imaging system enables the analysis of the bond wave and additionally micro mechanical structures as well as deformities in the silicon. This procedure allows also to analyze multiple layer bonds.[3] The image contrast depends on the distance between the wafers. Usually if using monochromatic IR the center of the wafers is display brighter based on the vicinity. Particles in the bond interface generate highly visible spots with differing contrast because of the interference fringes.[5] Unbonded areas can be shown if the void opening (height) is ≥ 1 nm.[4]

Fourier transform infrared (FT-IR) spectroscopy

The Fourier transform infrared (FT-IR) spectroscopy is a non-destructive hermeticity characterization method. The radiation absorption enables the analysis with a specific wavelength for gases. [6]

Ultrasonic microscopy

Ultrasonic microscopy uses high frequency sound waves to image bonded interfaces. The DI water is used as acoustic interconnect medium between the acoustic transducer and the wafer.[4][7]

This method works with an ultrasonic transducer scanning the wafer bond. The reflected sound signal is used for the image creation. The lateral resolutions depends on the ultrasonic frequency, the acoustic beam diameter and the signal-to-noise ratio (contrast).

Unbonded areas, i.e. impurities or voids, do not reflect the ultrasonic beam like bonded areas, therefore a quality assessment of the bond is possible.[3]

Double cantilever beam (DCB) test

Double cantilever beam test, also referred to as crack opening or razor blade method, is a method to define the strength of the bond. This is achieved by determine the energy of the bonded surfaces. A blade of a specific thickness is inserted between the bonded wafer pair. This leads to a split-up of the bond connection.[3] The crack length  equals the distance between the blade tip and the crack tip and is determined using IR transmitted light. The IR light is able to illuminate the crack, when using materials transparent to IR or visible light.[8] Is the fracture surface toughness very high, it is very difficult to insert the blade and the wafers are endangered to break at the slide in of the blade.[3]

equals the distance between the blade tip and the crack tip and is determined using IR transmitted light. The IR light is able to illuminate the crack, when using materials transparent to IR or visible light.[8] Is the fracture surface toughness very high, it is very difficult to insert the blade and the wafers are endangered to break at the slide in of the blade.[3]

The DCB test characterizes the time dependent strength by mechanical fracture evaluation and is therefore well suited for lifetime predictions.[9] A disadvantage of this method is, that between the entering of the blade and the time to take the IR image, the results can be influenced. In addition, the measurement inaccuracy increases with a high surface fracture toughness resulting in a smaller crack length or broken wafers at the blade insertion as well as the influence of the fourth power of the measured crack length. The measured crack length determines surface energy  in relation to a rectangular, beam-shaped specimen.

in relation to a rectangular, beam-shaped specimen.

Thereby is  the Young's modulus,

the Young's modulus,  the wafer thickness,

the wafer thickness,  the blade thickness and

the blade thickness and  the measured crack length.[10] In literature different DCB models are mentioned, i.e. measurement approaches by Maszara, Gillis and Gilman, Srawley and Gross, Kanninen or Williams. The most commonly used approaches are by Maszara or Gillis and Gilman.[8]

the measured crack length.[10] In literature different DCB models are mentioned, i.e. measurement approaches by Maszara, Gillis and Gilman, Srawley and Gross, Kanninen or Williams. The most commonly used approaches are by Maszara or Gillis and Gilman.[8]

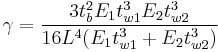

Maszara model

The Maszara model neglects shear stress as well as stress in the un-cleaved part for the obtained crack lengths. The compliance of a symmetric DCB specimen is described as follows:

The compliance is determined out of the crack length  , the width

, the width  and the beam thickness

and the beam thickness  .

.  defines the Young's modulus. The surface fracture energy

defines the Young's modulus. The surface fracture energy  is:

is:

with  as load-point displacement.

as load-point displacement.

Gillis and Gilman model

The Gillis and Gilman approach considers bend and shear forces in the beam. The compliance equation is:

The first term  describes the strain energy in the cantilever due to bending. The second term is the contribution from elastic deformations in the un-cleaved specimen part and the third term considers the shear deformation. Therefore

describes the strain energy in the cantilever due to bending. The second term is the contribution from elastic deformations in the un-cleaved specimen part and the third term considers the shear deformation. Therefore  and

and  are dependent on the conditions of the fixed end of the cantilever. The shear coefficient

are dependent on the conditions of the fixed end of the cantilever. The shear coefficient  is dependent on the cross-section geometry of the beam.

is dependent on the cross-section geometry of the beam.

Chevron test

The chevron test is used to determine the fracture toughness  of brittle construction materials. The fracture toughness is a basic material parameter for analyzing the bond strength.

of brittle construction materials. The fracture toughness is a basic material parameter for analyzing the bond strength.

The chevron test uses a special notch geometry for the specimen that is loaded with an increasing tensile force. The chevron notch geometry is commonly in shape of a triangle with different bond patterns. At a specific tensile load the crack starts at the chevron tip and grows with continuous applied load until a critical length is reached.[11] The crack growth becomes unstable and accelerates resulting in a fracture of the specimen.[8] The critical length depends only on the specimen geometry and the loading condition. The fracture toughness commonly  is determined by measuring the recorded fracture load of the test. This improves the test quality and accuracy and decreases measurement scatter.[11]

is determined by measuring the recorded fracture load of the test. This improves the test quality and accuracy and decreases measurement scatter.[11]

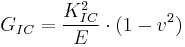

Two approaches, based on energy release rate  or stress intensity factor

or stress intensity factor  , can be used for explaining the chevron test method.[8] The fracture occurs when

, can be used for explaining the chevron test method.[8] The fracture occurs when  or

or  reach a critical value, describing the fracture toughness

reach a critical value, describing the fracture toughness  or

or  . The advantage using chevron notch specimen is due to the formation of a specified crack of well-defined length.[12] The disadvantage of the approach is that the gluing required for loading is time consuming and may induce data scatter due to misalignment.[8]

. The advantage using chevron notch specimen is due to the formation of a specified crack of well-defined length.[12] The disadvantage of the approach is that the gluing required for loading is time consuming and may induce data scatter due to misalignment.[8]

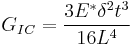

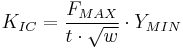

Micro chevron (MC) test

The micro chevron (MC) test is a modification of the chevron test using a specimen of defined and reproducible size and shape. The test allows the determination of the critical energy release rate  and the critical fracture toughness

and the critical fracture toughness  .[13] It is commonly used to characterize the wafer bond strength as well as the reliability. The reliability characterization is determined based on the fracture mechanical evaluation of critical failure.[9] The evaluation is determined by analyzing the fracture toughness as well as the resistance against crack propagation.[10]

.[13] It is commonly used to characterize the wafer bond strength as well as the reliability. The reliability characterization is determined based on the fracture mechanical evaluation of critical failure.[9] The evaluation is determined by analyzing the fracture toughness as well as the resistance against crack propagation.[10]

The fracture toughness allows comparison of the strength properties independent on the particular specimen geometry.[12] In addition, bond strength of the bonded interface can be determined.[11] The chevron specimen is designed out of bonded stripes in shape of a triangle. The space of the tip of the chevron structure triangle is used as lever arm for the applied force. This reduces the force required to initiate the crack. The dimensions of the micro chevron structures are in the range of several millimeters and usually an angle of 70 ° chevron notch.[13] This chevron pattern is fabricated using wet or reactive ion etching.[12]

The MC test is applied with special specimen stamp glued onto the non-bonded edge of the processed structures. The specimen is loaded in a tensile tester and the load is applied perpendicular to the bonded area. When the load equals the maximum bearable conditions, a crack is initiated at the tip of the chevron notch.´[13]

By increasing the mechanical stress by means of a higher loading, two opposing effects can be observed. First, the resistance against the crack expansion increases based on the increasing bonding of the triangular shaped first half of the chevron pattern. Second, the lever arm is getting longer with increased crack length  . From the critical crack length

. From the critical crack length  an instable crack expansion and the destruction of the specimen is initiated.[13] The critical crack length

an instable crack expansion and the destruction of the specimen is initiated.[13] The critical crack length  corresponds to the maximum force

corresponds to the maximum force  in a force-length-diagram and a minimum of the geometric function

in a force-length-diagram and a minimum of the geometric function  .[14]

.[14]

The fracture toughness  can be calculated with maximum force, width

can be calculated with maximum force, width  and thickness

and thickness  :

:

The maximum force  is determined during the test and the minimal stress intensity coefficient

is determined during the test and the minimal stress intensity coefficient  is determined by FE Simulation.[15] In addition, the energy release rate

is determined by FE Simulation.[15] In addition, the energy release rate  can be determined with

can be determined with  as modulus of elasticity and

as modulus of elasticity and  as Poisson's ratio in the following way.´[13]

as Poisson's ratio in the following way.´[13]

The advantage of this test is the high accuracy compared to other tensile or bend tests. It is an effective, reliable and precise approach for the development of wafer bonds as well as for the quality control of the micro mechanical device production.[12]

Shear test

Shear testing is a method to determine the average strength and local stress the bonding layer can withstand. It is used to determine the integrity of materials and procedures and evaluate the overall performance of the bonding frame and to compare various bonding technologies with each other.[9] It is based on measuring the applied force, the failure type due to the applied force and the visual appearance of the residual medium used. The contact tool is required to apply uniform force over the whole contact area. The top tool applies a force on the test medium that is sufficient to shear the specimen. The applied force used equals the maximum shear strength the connection can withstand.[16]

A test device as shown in the image is commonly used to determine the shear strength. Two skids are pressed together. The top tool provides the applied force. The bottom tool holds the specimen and is mounted on a movable skid to ensure that only shear forces effect the specimen.

Shear test

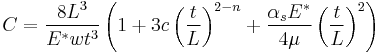

White Light Interferometers

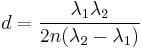

White light interferometry is commonly used for detecting deformations of the wafer surface based on optical measurements. Low-coherence light from a white light source passes through the optical top wafer, e.g. glass wafer, to the bond interface. Usually there are three different white light interferometers:

- diffraction grating interferometers

- vertical scanning or coherence probe interferometers

- white light scatter plate interferometers

For the white light interferometer the position of zero order interference fringe and the spacing of the interference fringes needs to be independent of wavelength.[17] White light interferometry is utilized to detect deformations of the wafer. Low coherence light from a white light source passes through the top wafer to the sensor. The white light is generated by a halogen lamp and modulated. The spectrum of the reflected light of the sensor cavity is detected by a spectrometer. The captured spectrum is used to obtain the cavity length of the sensor. The cavity length d corresponds to the applied pressure and is determined by the spectrum of the reflection of the light of the sensor. This pressure value is subsequently displayed on a screen. The cavity length  is determined using

is determined using

with  as refractive index of the sensor cavity material,

as refractive index of the sensor cavity material,  and

and  as adjacent peaks in the reflection spectrum.

as adjacent peaks in the reflection spectrum.

The advantage of using white light interferometry as characterization method is the influence reduction of the bending loss.[18]

See also

- Wafer bonding

- Direct bonding

- Plasma activated bonding

- Anodic bonding

- Eutectic bonding

- Glass frit bonding

- Adhesive bonding

- Thermocompression bonding

- Reactive bonding

References

- ^ a b Khan, M. F. and Ghavanini, F. A. and Haasl, S. and Löfgren, L. and Persson, K. and Rusu, C. and Schjølberg-Henriksen, K. and Enoksson, P. (2010). "Methods for characterization of wafer-level encapsulation applied on silicon to LTCC anodic bonding". Journal of Micromechanics and Microengineering 20 (6): pp. 064020. doi:10.1088/0960-1317/20/6/064020.

- ^ Cui, Z. (2008). "Anodic Bonding". Springer Science+Business Media, LLC.. pp. 50-54. ISBN 978-0-387-48998-8.

- ^ a b c d e f Mack, S. (1997). Eine vergleichende Untersuchung der physikalisch-chemischen Prozesse an der Grenzschicht direkt und anodischer verbundener Festkörper (Report). ISBN 3-18-343602-7.

- ^ a b c Farrens, S. (2008). "Metal Based Wafer Level Packaging". Global SMT & Packaging.

- ^ Weldon, M. K. and Marsico, V. E. and Chabal, Y. J. and Hamann, D. R. and Christman, S. B. and Chaban, E. E. (1996). "Infrared spectroscopy as a probe of fundamental processes in microelectronics: silicon wafer cleaning and bonding". Surface Science 368 (1-3): pp. 163-178. doi:10.1016/S0039-6028(96)01046-1.

- ^ Lin, Y.-C. and Baum, M. and Haubold, M. and Fromel, J. and Wiemer, M. and Gessner, T. and Esashi, M. (2009). "Development and evaluation of AuSi eutectic wafer bonding". Solid-State Sensors, Actuators and Microsystems Conference, 2009. TRANSDUCERS 2009. International. pp. 244-247. doi:10.1109/SENSOR.2009.5285519.

- ^ Sood, S. and Thomas, R. and Adams, T. (2008). "Acoustic Characterization of Bonded Wafers". ECS Transactions 16: pp. 425-428. doi:10.1149/1.2982896.

- ^ a b c d e f g Vallin, Ö. and Jonsson, K. and Lindberg, U. (2005). "Adhesion quantification methods for wafer bonding". Materials Science and Engineering: R: Reports 50 (4-5): pp. 109-165. doi:10.1016/j.mser.2005.07.002.

- ^ a b c Nötzold, K. and Graf, J. and Müller-Fiedler, R. (2008). "A four-point-bending-test for the stability assessment of glass frit bonded molded microsensors". Microelectronics Reliability 48 (8-9): pp. 1562-1566. doi:10.1016/j.microrel.2008.07.001.

- ^ a b Wünsch, D. and Müller, B. and Wiemer, M. and Gessner, T. and Mischke, H. (May 2010). "Aktivierung mittels Niederdruckplasma zur Herstellung von Si-Verbunden im Niedertemperatur-Bereich und deren Charakterisierung mittels Mikro-Chevron-Test". Technologien und Werkstoffe der Mikrosystem- und Nanotechnik (GMM-Fachbereicht Band 65). VDE Verlag GmbH Berlin Offenbach. pp. 66-71. ISBN 978-3-8007-3253-1.

- ^ a b c Wiemer, M. and Frömel, J. and Chenping, J. and Haubold, M. and Gessner, T. (2008). "Waferbond technologies and quality assessment". Electronic Components and Technology Conference, 2008. ECTC 2008. 58th. pp. 319-324. doi:10.1109/ECTC.2008.4549989.

- ^ a b c d e Petzold, M. and Knoll, H. and Bagdahn, J. (2001). "Strength assessment of wafer-bonded micromechanical components using the Micro-Chevron-Test". Reliability, Testing, and Characterization of MEMS/MOEMS. doi:10.1117/12.442994.

- ^ a b c d e Schneider, A. and Rank, H. and Müller-Fiedler, R. and Wittler, O. and Reichl, H. (2009). "Stabilitätsbewertung eutektisch gebondeter Sensorstrukturen auf Waferlevel". In Hermann, G.. 9. Chemnitzer Fachtagung Mikromechanik & Mikroelektronik. pp. 51-56.

- ^ Petzold, M. and Dresbach, C. and Ebert, M. and Bagdahn, J. and Wiemer, M. and Glien, K. and Graf, J. and Müller-Fiedler, R. and Höfer, H. (2006). "Fracture mechanical life-time investigation of glass frit-bonded sensors". The Tenth Intersociety Conference on Thermal and Thermomechanical Phenomena in Electronics Systems, 2006. ITHERM '06.. pp. 1343-1348. doi:10.1109/ITHERM.2006.1645501.

- ^ Vogel, K. and Wünsch, D. and Shaporin, A. and Mehner, J. and Billep, D. and Wiemer, D. (2010). "Crack propagation in micro-chevron-test samples of direct bonded silicon-silicon wafers". 9th Youth Symposium on Experimental Solid Mechanics. pp. 44-47.

- ^ "Method 2019.7 (Die Shear Strength)". March 2003.

- ^ Wyant, J. C. (2002). "White Light Interferometry". Proceedings of SPIE 4737: pp. 98-107.

- ^ Totsu, K. and Haga, Y. and Esashi, M. (2005). "Ultra-miniature fiber-optic pressure sensor using white light interferometry". Journal of Micromechanics and Microengineering 15 (1): pp. 71-75. http://stacks.iop.org/0960-1317/15/i=1/a=011.